Characteristic

- 1. With the jumping device in the scoring saw and the first milling unit, can prevent tearing effectively when processing.

- 2. Design with separation-type scoring saw and cut-off saw,it is convenient for the customer to choose working as top spindle or bottom spindle according to different type of products.

- 3. Sanding device has ashock function,sanding pad can automatically adjust the stretch.

- 4. Peculiar polishing devicecan remove the residual wood chips and other impuritiesensure smooth and uniform on workpiece surface.

- 5. Each spindle can rotate, convenient to achieve angle-truncate, tenon, groove and etc.

- 6. Adopted widen by high precision linear orbit, machine can run in precision and wearable. It assure the precision when widen the working size, also can guarantee to fit your highly requirement for setting the working width.

- 7. Orbit lubrication can reduce the frictions of slide when moving, increase the nature life of orbit as well.

- 8. The cut-off saw equipped 11KW motor and can be installed hoggers, which is quite suitable to process the big cutting capacity materials.

- 9. The design of rigid column and carriage to ensure the needs of heavy-duty cutting.

- 10. Much better to feed the big size panels with the lengthen chain belt design.

- 11. Supported with the roller bearing in the feeding belt, make the movement more stable and reduce the noise.

- 12. In order to assure every chain board with high precision, we use the high hardness cast iron and treated with high temperature and machining by CNC.

- 13. Top pressure and bottom conveyor belt has the design of two different speeds, no matter before or behind the fence dot, can be achieved to feed against the benchmark.

- 14. Individual transmission shaft seat structure makes operation of the chain more stable.

- 15. Each spindle is equipped with high precision bearing, spindle speed of milling units reach to 7500r/min.

- 16. Adjustable height on in-feed fence is better satisfied with basis positioning requirements for different thickness of wood panel.

- 17. Each spindle is configured with read out,can display the position of spindle veracious.

- 18. Width between two orbits of machine base reaches to 1105mm.Stronglyspare parts improve the machine stable effectively.

- 19. Adopted inverter for feeding, make the feed speed reaches to 5~25m/min, increase the productivity.

- 20. Setting all of the parameter by PLC, easy to view and control. Reduce labour and the time for setting parameter, improve the productivity effectively.

- 21. Adopted the high class electric component to build up the perfect electric system can increase the stabilization.

- 22. Through the automatic locking which controlled by PLC, can lock the linear orbit automatically. Not only can reduce the labour but also can assure the stable of the machine base, improve the quality of the work pieces.

- 23. Adopted excellent material to make of the pressure belt, keep good wearable.

- 24. Only input value of working width and thickness to the PLC, you can control the width and thickness. Precision of setting width is ±0.1mm. Easy to locate the workpieces and convenient to operate.

- 25. To equip with out-feed guide roller.

- 26. Sealed safety enclosure is controlled by pneumatic, can reduce noise levels, improve extraction and operator safety.

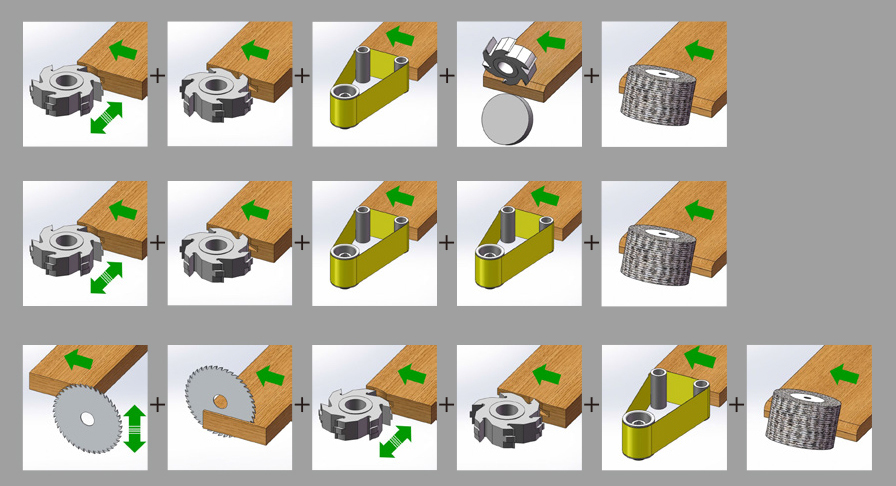

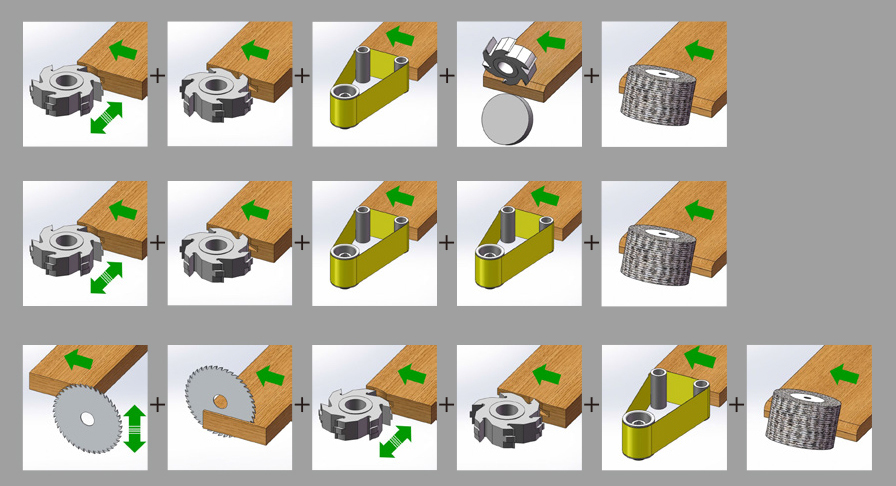

D120M cutter shaft arrangement diagram

Technical Parameter

Specification &type

|

RMD1225

|

| Working Thickness (mm) |

10-120 |

| Working Width (mm) |

250-2500 |

| Cutting cirdle(max~min)(mm) |

Left Saw unit |

Ø125-Ø200 |

| Right Saw unit |

Ø125-Ø200 |

| Left cut~off Saw |

Ø250-Ø300 |

| Right cut~off Saw |

Ø250-Ø300 |

| First left and right milling unit |

Ø140-Ø160 |

| Second left and right milling unit |

Ø140-Ø160 |

| Polishing unit |

Ø230 |

| Spindle diameter (mm) |

Left Saw uni |

Ø25.4 |

| Right Saw unit |

Ø25.4 |

| Left cut~off Saw |

Ø40 |

| Right cut~off Saw |

Ø40 |

| Thickness of saw blade |

1.4-3.2mm |

| First left and right milling unit |

Ø40 |

| Second left and right milling unit |

Ø40 |

| Left and right polishing unit |

Ø25.4 |

| Max length of milling unit (mm) |

First left and right milling unit |

100 |

| Second left and right milling uni |

135 |

| Basic motor power (kW) |

Left Saw uni |

3kW/4HP |

| Left and right saw unit |

3kW/4HP |

| Left and right cut-off Saw |

11kW/15HP |

| Left and right milling head |

5.5kW/7.5HP

|

| Second left and right milling unit |

2×7.5kW/10HP |

| Left and right sanding unit |

2×2.2kW/3HP |

| Feed |

3kW/4HP |

| Widen |

1.1kW/1.5HP |

| Left and right polishing unit |

2×2.2kW/3HP |

| Left and right polishing unit swing |

2×0.12kW/0.16HP |

| Pressure bet lit |

2x0.25kW/0.33HP |

| Total motor power(standard (kW) |

67.64kW/92HP |

| Feed speed (m/min) |

5-25 |

| spindle speed((/min) |

First left and right milling unit |

9000 |

| Second left and right milling unit |

7500 |

| Linearity speed of sanding belt(m/s) |

8-13.5m/s |

| Dust outlet diameter(mm |

Ø116/Ø120 |

Dwerall machne dimensions (LxWxH

(mm) |

5000×5395×2100 |

| Weight(Tons apprax) |

7 |

Note: Any variation to the specification above mentioned will not be further notified since the product specification and designs keeps on changing.