Maintenance of REIGNMAC machines

@All customers, please accept this 4 side planer, Double end tenoner maintenance strategy.

The Spring Festival holiday is coming, and it is time to stop the equipment and carry out pre-holiday maintenance. In order to ensure that the equipment is in good condition in the coming year, here is a warm reminder to all customers to maintain the Four-side planer and Double-end tenoner before the vacation The detailed precautions are as follows:

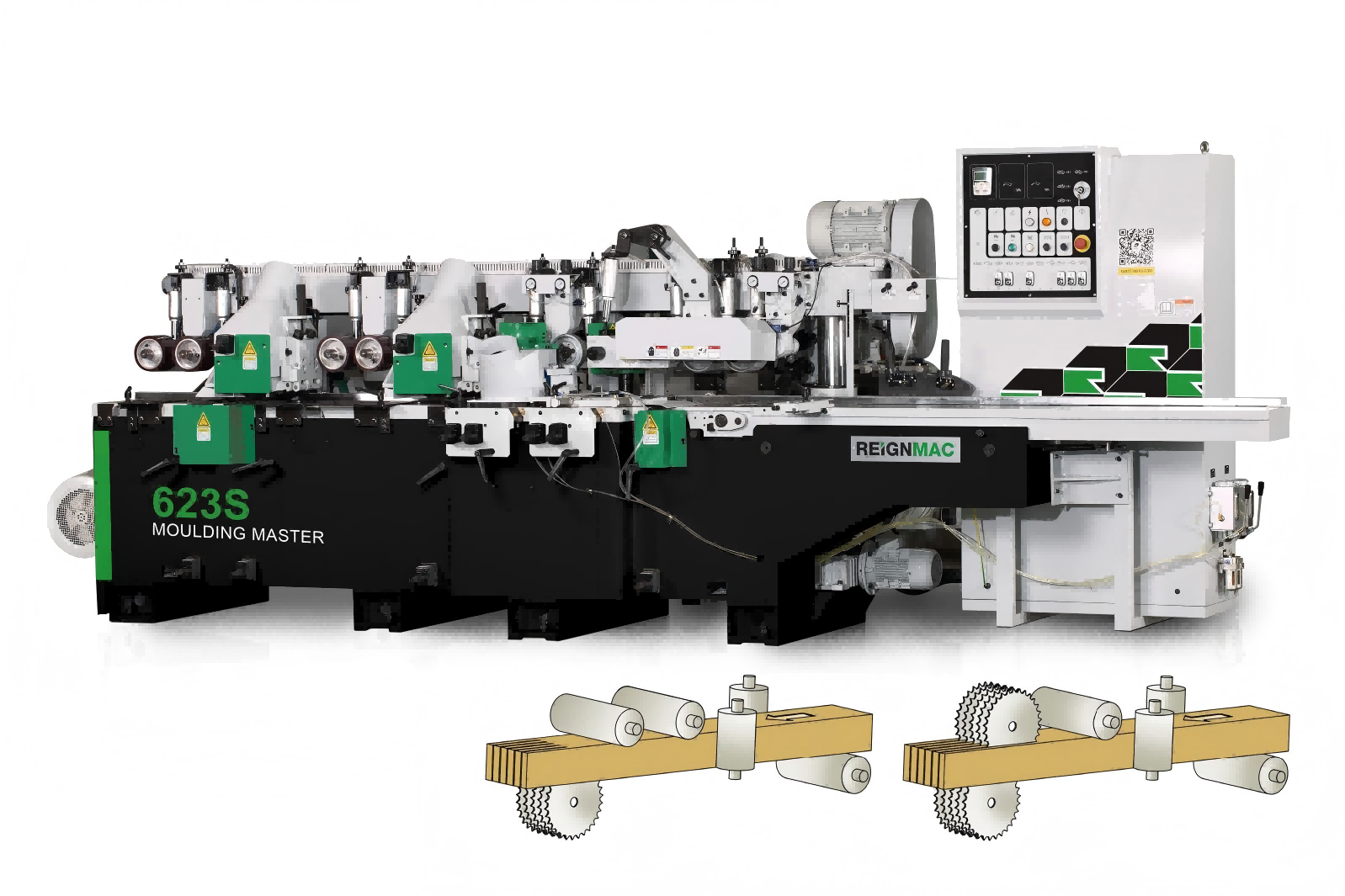

Four-side planer:

(1)Clean the Four side planer and blow off the sundries or sawdust on the machine with an air gun.

(2)Check the 4 side planer reducer of the feeding mechanism for leakage, check the oil level on the oil level mirror, and fill the oil when the oil is not visible on the oil level mirror.

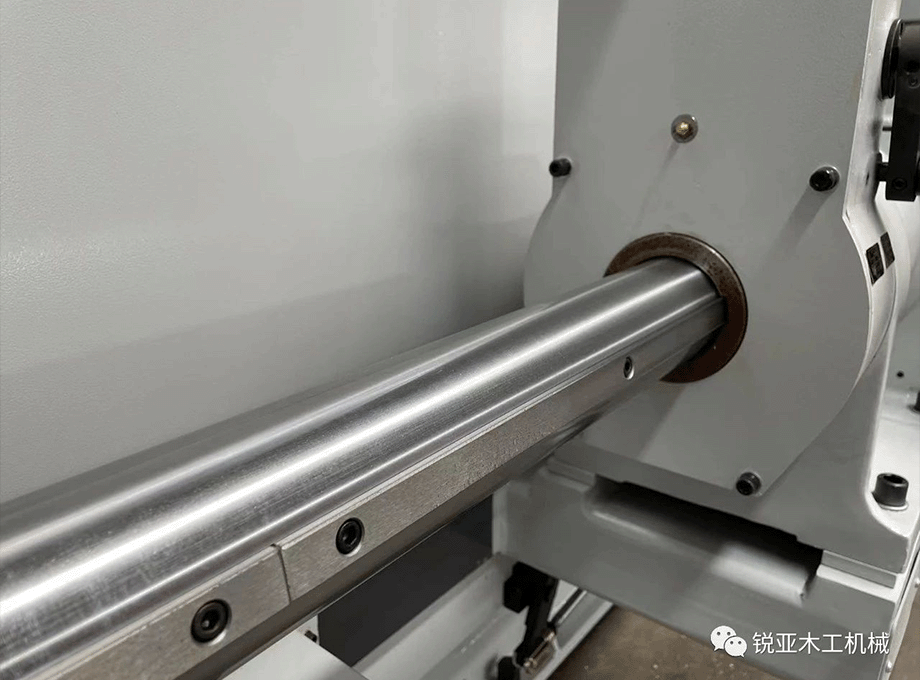

(3)Apply grease to the Four side moulder feeding mechanism of the such as the lifting screw rod, and install the dust boot.

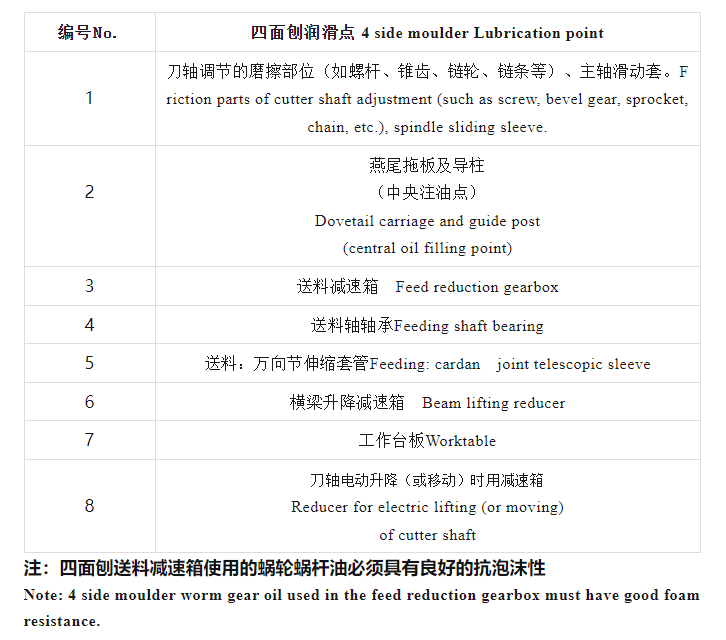

(4)Maintenance of Four side planer lubrication points :

(5)Antirust oil shall be sprayed on the position where the 4 side planer is prone to rust iron parts to prevent rust.

(6)Check whether the power streamer and cable are worn, and deal with them in time if any. Switch off the main power supply of the equipment and place a drying bag to prevent damage to electrical components caused by moisture.

(7)It is recommended to pack the equipment with plastic film to prevent rats from entering and biting the line.

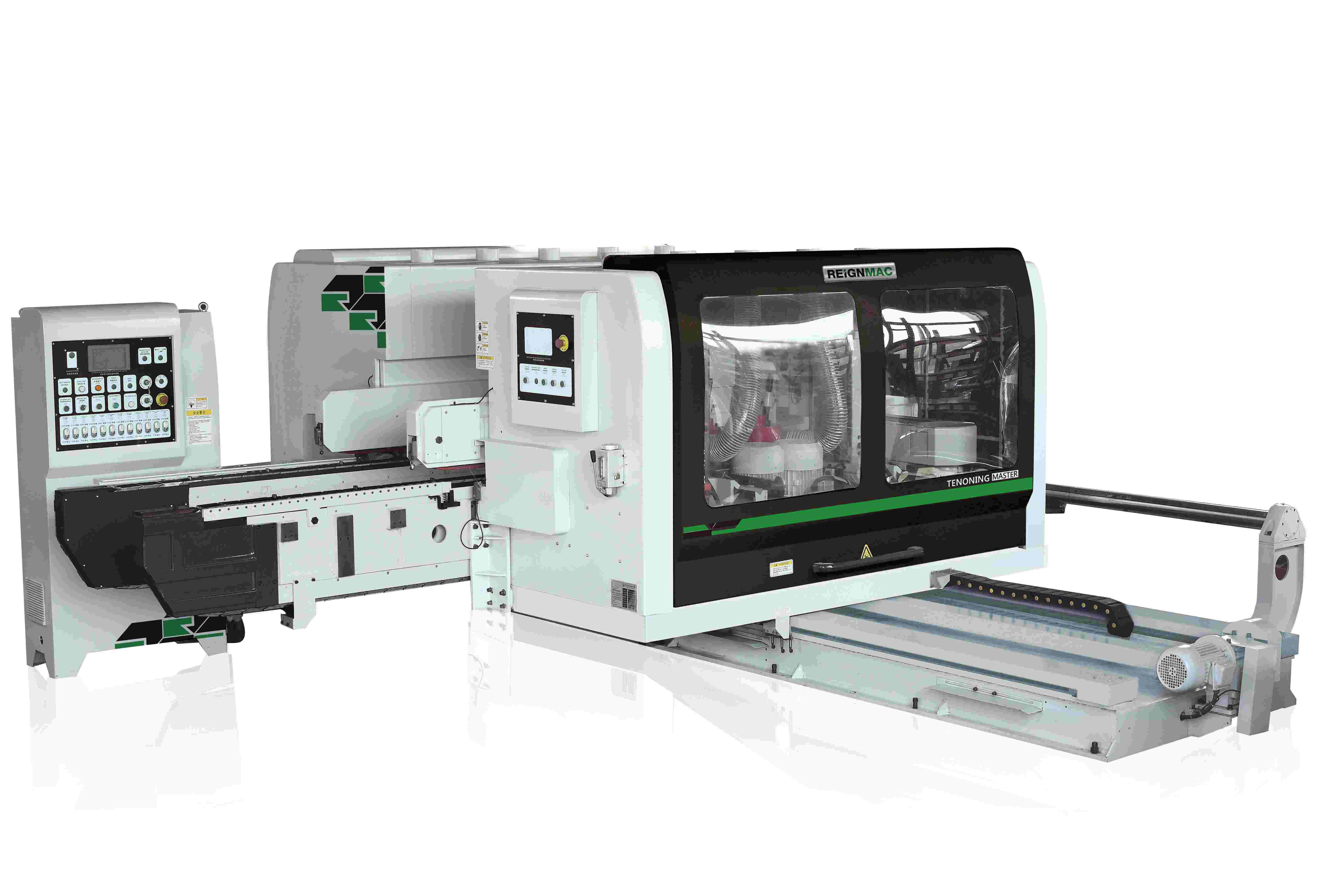

Double End Tenoner:

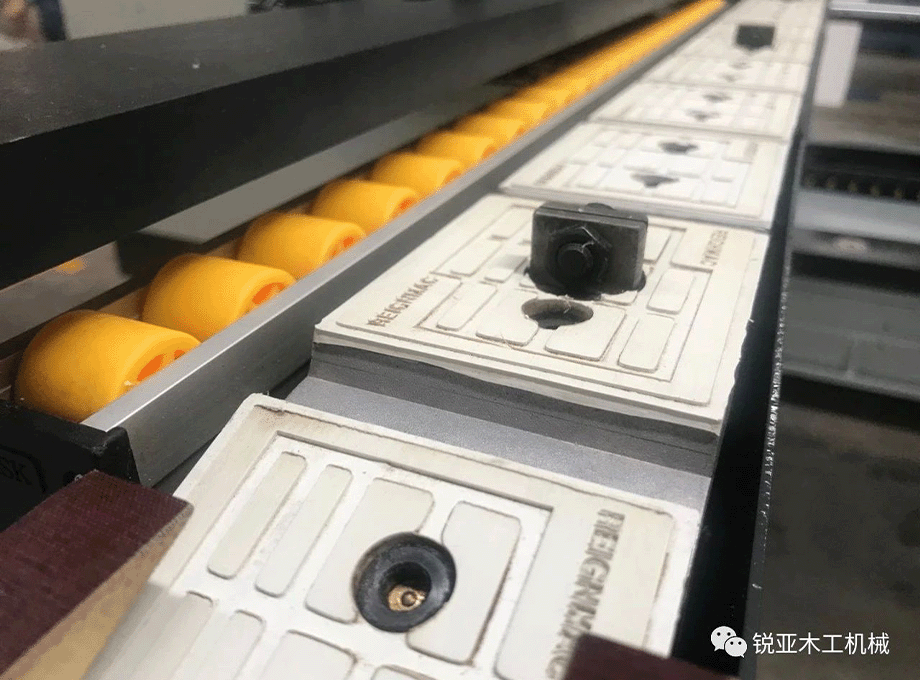

(1)Check and remove the sundries or sawdust on the chain belt slideway and dust and sundries in the tenoner. Each chain belt mandrel has lubrication points, which can be refueled if necessary to keep the chain link flexible.

(2)Properly store the removed saw blade and milling cutter. The motor spindle can be properly coated with anti-rust oil to maintain lubrication.

(3)Check the Double end tenoner worm gear reducer for oil leakage, check the oil level, and fill oil when the oil level is lower than the oil mirror.

(4)Check whether the power streamer and cable are worn, and deal with them in time if any. Turn off the main power supply of the equipment and place a drying bag to prevent damage to electrical components caused by moisture.

(5)Check the electrical components for damage and leakage, and close the air circuit.

(6)It is recommended to pack the Double end tenoner with plastic film to prevent rats from entering and biting the line.